20.08.2021 "Climate-neutral printing inks process"

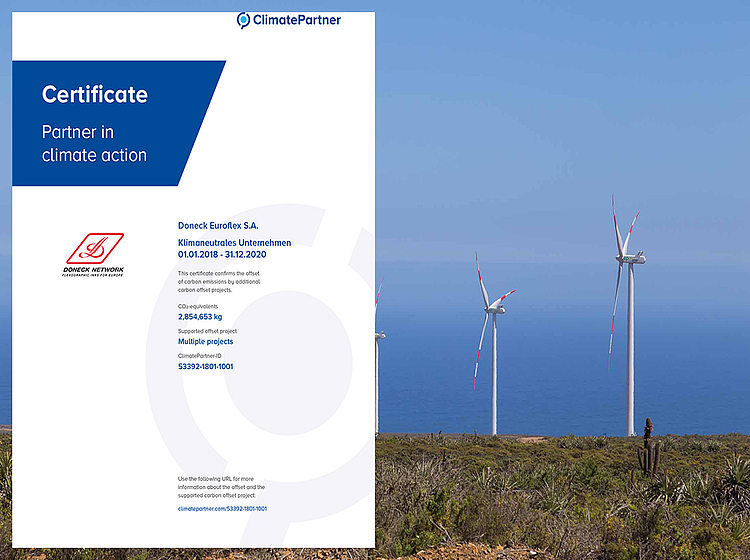

The entire manufacturing process at the Doneck headquarters in Luxembourg has been climate-neutral since 2018. This is confirmed by the certified carbon footprint.

The climate-neutral compensation is currently achieved through the promotion of clean wind power in Ovalle, Chile. In the preceding years it was two other projects: a forest protection project in Brazil and an emission reduction programme in Peru. The climate protection specialist ClimatePartner certifies this for Doneck in its certificate.

In addition, Doneck actively practises extensive environmental protection: e.g. through the avoidance and reduction of waste (e.g. plastic), reusable instead of disposable packaging, electromobility, electricity from hydroelectric power (since 2011) and green gas (since 2018), and some other things. Doneck continuously optimises its sustainability strategy with the guiding principle "We think green".

Photo: Certificate and wind power in Chile (source: ClimatePartner)

Link Climate Partner: https://fpm.climatepartner.com/tracking/53392-1801-1001/de?utm_source=climatepartner.com&utm_medium=id