No matter whether they are printing inks for direct food contact, for compostable packaging or for use with baking. The Doneck Network has developed proven ink series for these specialist applications.

Food packaging has to fulfil a variety of functions. Its primary task is to protect the respective product on its journey from packing by the manufacturer to consumption by the consumer. This protection may be against factors ranging from damage and contamination to environmental influences (temperature, precipitation, sunlight etc.). Nevertheless, the first priority is to protect people from migration of substances between the product and the packaging and resulting contamination. Packaging facilitates the transport of the products from the producer to the POS (Point of Sales) and thence to the consumer. Once they have arrived there, they should be storable. The packaging is, furthermore, also the source of information regarding ingredients, origin etc. In addition, it is the marketing instrument for sale at the POS and for advertising the product. The consumer decides whether or not to buy in just three to seven seconds. In a survey, 85% of consumers indicated that the coloured design was the main reason for their decision to purchase. If the packaging needs for a product are diverse, then the requirements for food packaging are just as varied. Added to these are the technical properties and requirements, such as materials (paper, films) and their usage from production to disposal. Will the packaging be exposed to high (e.g. when heated in an oven) or low (e.g. when cooled in a freezer) temperatures? It is in direct contact with the food? Must the packaging be compostable? These and many other questions underline the high demands that are made of food packaging.

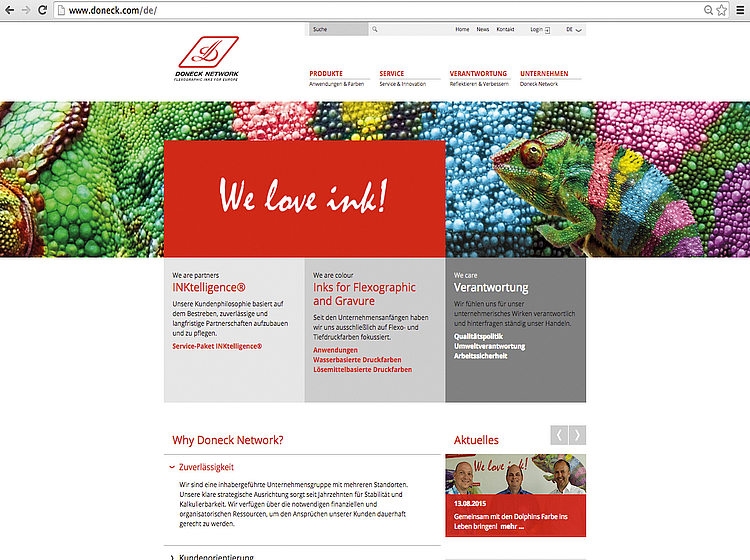

Apart from the technical printing specifications, the printing ink manufacturer must take appropriate account of these requirements in particular. The Doneck Network, which enjoys a good reputation on the market for consumer goods applications and whose management system is hygiene certified to DIN EN ISO 22000, has been approached increasingly frequently in the past by packaging manufacturers regarding products for the specialised applications mentioned above and has developed a suitable ink series for this purpose.

The Euro-Contact series of water-based inks used in combination with an overprint varnish from Doneck are suitable for direct contact with food. This opens up entirely new dimensions for the food packaging industrial sector. The product safety management of the Doneck Network classes this product application as particularly sensitive and uses the services of an independent, accredited laboratory to ensure compliance with food safety law. The Doneck Network laboratory teams have carried out painstaking development work and have created an ink series that has been tested and certified by the ISEGA. These inks are used for the printing of cardboard; they can be used for post-printing on coated, uncoated and smoothed papers, and for pre-printing on uncoated papers. For example, fruit and vegetable trays, pizza cartons and cake mats may be printed with this printing ink series. The Euro-Contact range scores points for its excellent printability and very good stability at the printing machine.

A still greater challenge for the printing ink developers of the Doneck Network is presented by the use of printing inks for muffin cups. Because the paper muffin cups are heated together with the food in the oven to a temperature of 220°C for a significant length of time, the issue of migration arises once again under these more demanding conditions. Even at temperatures as high as this, there must be no detectable transfer of ink substances to the food or, as the case may be, compliance with the legally stipulated SMLs (specific migration limits) must be maintained. Furthermore, a special selection of raw materials must be evaluated with the purpose of ensuring that they cannot break down to produce harmful substances at temperatures as high as this. The ISEGA certificate that has been issued confirms the safety of the Euro-Food WSG ink series for printing muffin cups.

A completely different, but no less important market trend is the demand for the compostability of printed packaging. Of importance here is the printed inks that is used as well as the other packaging components. As the result of a lengthy series of tests by independent experts, the Doneck Network has been able to determine that, by making the appropriate selection of pigments, several ink series for different applications may be considered to be compostable in accordance with EN 13432 and can be marked with the “OK Compost” and “OK Compost Home” conformity marks. All of the components of the ink series have been undergone rigorous tests to check their respective heavy metal content and ecotoxicity. Evidence that there is no impairment whatsoever of plant growth is provided by 20-day cultivation tests of cress and spring wheat.

The water-based Euro Food ink series was developed accordingly for food packaging made of paper. This ink for bags and wrapping paper also meets the standard for bleeding resistance according to EN 646 and is odourless as well as low migration. The Euro Film printing ink series has been developed for the plastic film processing industry. It is characterised by good printability at the machine and good adhesion and resistance on PE/PP. The Euro Nap printing ink series has been developed for napkin and table covering applications. Used on tissue materials, such as paper napkins, pocket tissues, toilet paper or airlaids, this printing ink is odourless and gives good printing results on porous substrates.

“We have invested extensive development efforts and considerable testing costs in these product innovations in order to enable us to guarantee high product and consumer safety. I think that this effort has been very worthwhile for the consumer,” says Edgar Becker, Managing Director of Sales, with regard to the new printing ink series.

Photo: Paprika packaging for direct food contact