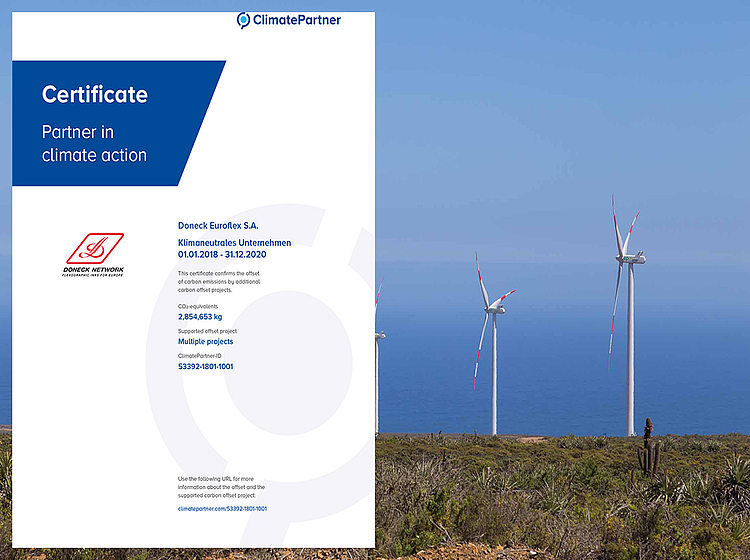

25.03.2024 Since 2018, Doneck Euroflex has been contributing financially to climate protection projects!

A valuable milestone in the Doneck strategy 2Bsustainable! We take responsibility for the future! Doneck Euroflex began to calculate its carbon footprint in 2018 and is thereby making a financial climate contribution* equivalent to the generated emissions in cooperation with ClimatePartner. This year, Doneck is financing and supports the wide-ranging expansion of renewable energies in Asia. In Asia, the certified climate protection projects are wind and solar energy, hydropower and biogas projects in various countries.

"We're transforming our company towards an environmentally friendly, socially responsible future which respects future generations!" Arndt Breitbach, CEO Doneck Network. “Sustainability is one of our strategic fields of action that helps us to advance our ambitious and measurable goals. Our sustainability strategy 2Bsustainable! focuses on defined sustainability targets that are achieved with the underlying sustainability programme. We document and publish our successful implementation annually in the Doneck Sustainability Report.

Along with this milestone, Doneck is optimising its entire value chain, from the purchase of raw materials and work in the laboratories to printing ink production and logistics, to ensure the company's best possible environmental compatibility at all times. The most important aspect of this is the implemented recycling system and our green workflow. The sustainability programme includes strategic environmental protection goals that are backed up with measurable key figures.

As a strong partner and solutions provider, Doneck focuses on the creation and development of innovative and practical products for the circular economy.

More information available at:.https://www.climatepartner.com/53392-1801-1001

*The contribution does not relate to indirect emissions that arise outside the company, such as in the manufacture of raw materials and preliminary products, external logistics and the use and disposal of products or other processes.

Photo: Climate Partner certificate